To control the geometrical parameters of high-precision products, a CMM is used with an accuracy of 0.002 mm. with 5-axis high-performance head RENISHAW Revo 2

The production complex TEN fab is equipped with modern equipment: milling, turning and turning-milling machines with numerical control, electroerosive, grinding equipment, laser cutting equipment, bending, welding, painting, assembly and assembly works.

We offer:

- 3-5 coordinate milling CNC machining

- Precision CNC machining

- turning and turning-milling CNC machining

- Electroerosive CNC machining

- sheet processing: laser cutting, CNC bending, welding, painting

- machine grinding

- turning and milling universal machining

- assembly and assembly work

- electric installation work

- assembly of equipment

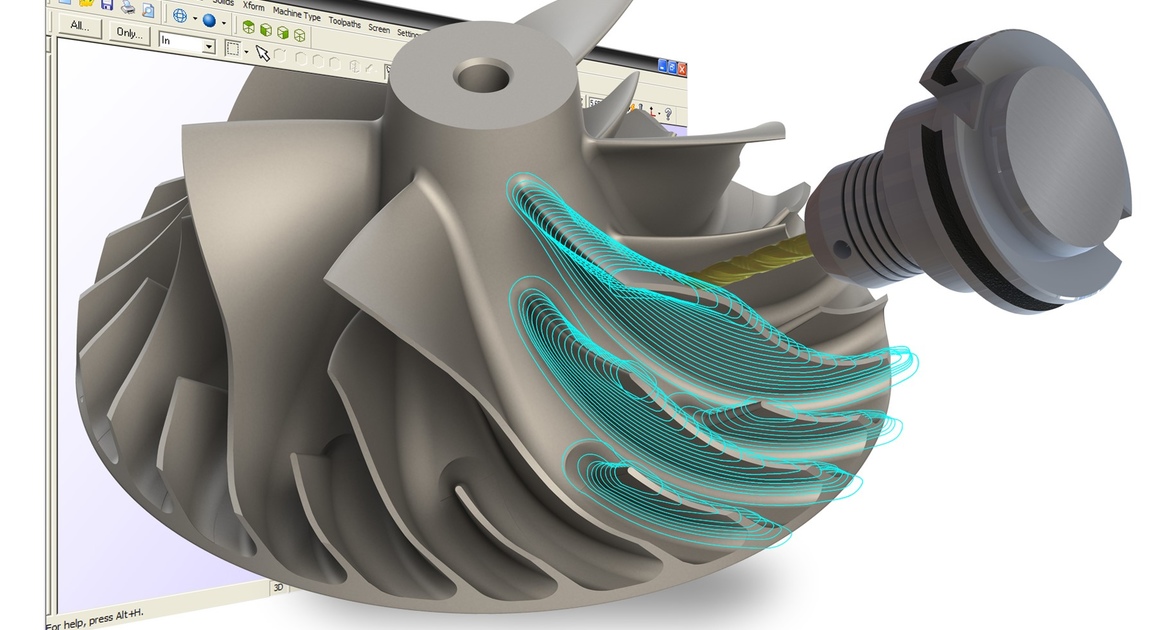

TEN fab performs milling operations of any complexity, both prototypes and small series, and serial products.

The machine park includes 3- and 5-axis machining centers with the possibility of high-speed milling. All equipment is equipped with instrument / part measuring systems during machining with automatic updating of correction parameters, which allows obtaining stable dimensional parameters of products. Part of the 3-axis machining centers is equipped with systems of 4- and 5-controlled coordinate axes, which extends their capabilities

Read more

TEN fab performs turning and turning-milling processing of metals, alloys and plastics on multifunctional processing turning centers, allowing to carry out the majority of operations of turning and milling. Machining centers are equipped with rod feed systems, counter spindle, wire tool systems, pneumatic systems with programmable force with accuracy up to 1 μm, instrument and part measuring systems, which makes it possible to manufacture precision parts.

Read more

Machine grinding is the most efficient finishing process for parts with high demands on accuracy and surface roughness. TEN FAB performs round, flat and thread grinding operations using specialized high-precision equipment.

Read more

TEN fab performs electroerosive wire-cut processing of any metals and alloys. Electro-erosion treatment allows obtaining a high level of parameters of accuracy and surface roughness. The absence of a mechanical effect makes it possible to produce thin-walled parts with practically perfect tolerances. The possibility of obtaining rounding radii at angles up to 0.025 mm, as well as machining metals with any hardness are in many cases a non-alternative solution to the problems of precision metalworking.

Read more

The range of thicknesses of metal cutting is 0.2-20 mm. Laser cutting of thin-sheet materials is a high-performance and precise method of metal working, which makes it possible to obtain products with high quality surfaces. CNC system allows you to cut metal on a complex contour with high accuracy and repeatability of dimensions

Read more

We offer the majority of types of assembly works: metal marking, metal cutting / plastic / rubber cutting, straightening and bending, drilling, threading, hole deployment, gluing, riveting, tinning, scraping, welding,

TEN fab has extensive experience in the manufacture of complex body products, welded structures, precision parts refinement, which guarantees high-quality results and short work execution time

Read moreTEN fab has an ISO9001 quality management system certificate.

We guarantee full compliance with the parameters of products documentation.

In the production process, the products undergo multi-stage operational and final control.

To control the geometrical parameters of high-precision products, a CMM is used with an accuracy of 0.002 mm. with 5-axis high-performance head RENISHAW Revo 2

The fixing system of workpieces equipped with zero points reduces machine changeover time, which reduces the time spent on the production of products at machining centers

The measurement system of the cutting tool reduces the time for changeover of machining centers and reduces the time spent on the production of products.

High-performance integrated CAD-CAM software allows you to quickly develop production technologies for products with complex geometry, which reduces the time spent on the production of prototypes and small series.